When using monomer liquid and polymer powder you – When using monomer liquid and polymer powder, it is essential to understand their properties and characteristics, as well as the proper procedures for mixing and handling these materials. This guide provides a comprehensive overview of monomer liquids and polymer powders, including their applications, advantages, and disadvantages.

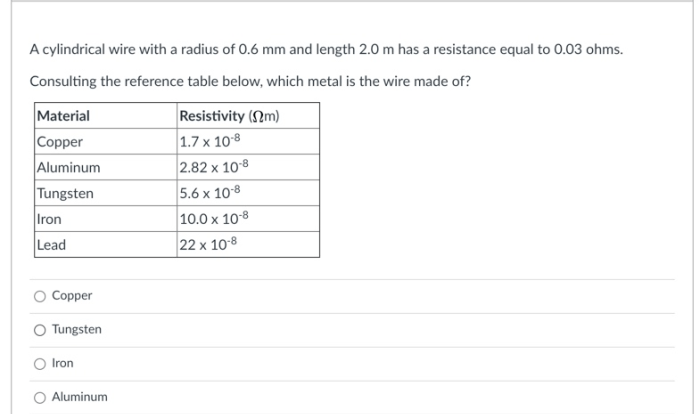

The physical and chemical properties of monomer liquids and polymer powders are distinct, and understanding these differences is crucial for successful use. Monomer liquids are typically low-viscosity fluids with high reactivity, while polymer powders are solid particles with a high molecular weight.

The mixing process involves combining these materials in specific proportions to achieve the desired properties.

1. Introduction

This analysis aims to explore the interactions between monomer liquids and polymer powders, highlighting their significance in various applications. Monomer liquids are low-molecular-weight compounds that can undergo polymerization reactions, while polymer powders are solid materials composed of high-molecular-weight polymer chains.

Understanding the properties and interactions of these materials is crucial for optimizing their performance and ensuring safe and efficient handling.

2. Properties and Characteristics

2.1 Monomer Liquids, When using monomer liquid and polymer powder you

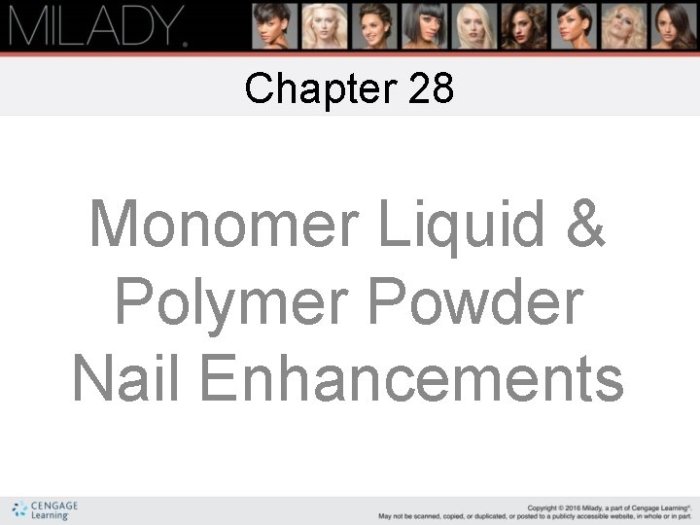

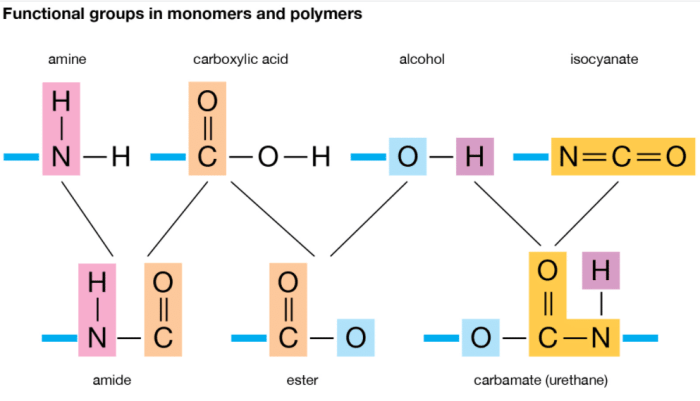

Monomer liquids are typically characterized by their low viscosity, high volatility, and reactive nature. They possess functional groups that enable them to undergo polymerization reactions, forming covalent bonds between molecules to create polymer chains.

2.2 Polymer Powders

Polymer powders, on the other hand, are solid materials with high molecular weights and low surface areas. They are typically inert and stable, with low reactivity and high resistance to solvents. Their properties depend on the type of monomer used and the polymerization process employed.

2.3 Comparison

- Monomer liquids are low-molecular-weight compounds with low viscosity, high volatility, and reactive functional groups.

- Polymer powders are high-molecular-weight solids with low surface areas, low reactivity, and high solvent resistance.

- The properties of both materials are influenced by the specific monomers used and the polymerization conditions.

3. Mixing and Handling: When Using Monomer Liquid And Polymer Powder You

Mixing monomer liquids and polymer powders requires careful procedures to ensure proper interaction and prevent potential hazards.

3.1 Mixing Procedures

Mixing should be done in a controlled environment with adequate ventilation. The monomer liquid is gradually added to the polymer powder while stirring or agitating to achieve a homogeneous mixture. The mixing ratio and temperature should be carefully controlled to optimize the reaction.

3.2 Safety Precautions

Monomer liquids and polymer powders can pose health and safety risks. Proper personal protective equipment (PPE), including gloves, eye protection, and respiratory masks, should be worn during handling. Adequate ventilation and grounding systems are essential to prevent explosions or fires.

3.3 Potential Hazards

- Improper mixing can lead to incomplete polymerization, resulting in a weak or brittle material.

- Excessive heat or incorrect mixing ratios can cause explosions or fires.

- Monomer liquids can release toxic fumes or vapors, requiring proper ventilation and respiratory protection.

4. Applications

Monomer liquids and polymer powders are widely used in various industries, including:

4.1 Adhesives and Sealants

Monomer liquids can be used as adhesives or sealants when mixed with polymer powders. The resulting material forms strong bonds between surfaces, making it suitable for applications such as construction, automotive, and packaging.

4.2 Coatings and Paints

Monomer liquids and polymer powders are used in the formulation of coatings and paints. The combination provides a durable, protective layer that resists wear, corrosion, and chemicals.

4.3 Composites

Polymer powders are often reinforced with fibers or other materials to create composites. Monomer liquids can be used to impregnate the composite, improving its strength and stiffness.

4.4 Advantages and Disadvantages

- Advantages:High strength, durability, versatility, and cost-effectiveness.

- Disadvantages:Potential health and safety risks, environmental concerns, and limited shelf life.

5. Alternative Materials

In some applications, alternative materials can be used instead of monomer liquids and polymer powders. These include:

5.1 Thermoset Resins

Thermoset resins are liquid materials that undergo irreversible chemical reactions upon heating, forming a solid network. They offer high strength, heat resistance, and electrical insulation.

5.2 Thermoplastic Elastomers

Thermoplastic elastomers are rubber-like materials that combine the properties of plastics and rubbers. They exhibit elasticity, flexibility, and durability, making them suitable for applications such as automotive parts and medical devices.

5.3 Factors to Consider

- Cost and availability

- Required properties (strength, flexibility, durability)

- Processing requirements

- Environmental and safety concerns

Helpful Answers

What are the safety precautions when handling monomer liquids and polymer powders?

Monomer liquids and polymer powders can be hazardous if not handled properly. It is important to wear appropriate protective gear, such as gloves, eye protection, and a respirator, when working with these materials. Adequate ventilation is also essential to prevent inhalation of harmful fumes.

What are the advantages of using monomer liquids and polymer powders?

Monomer liquids and polymer powders offer several advantages, including high strength, durability, and resistance to chemicals and solvents. They are also lightweight and easy to mold, making them suitable for a variety of applications.